Ever wondered what makes bourbon such a distinct and cherished American spirit?

Bourbon, unlike any other whiskey, is steeped in tradition and stringent rules.

You Are Watching: What Is Bourbon Made From Updated 07/2025

In this article, we unravel the mystery of its ingredients and production process that craft its unique character.

Stay with us as we embark on a flavorful journey into the heart of bourbon’s recipe.

The Ingredients of Bourbon

Bourbon is made from a combination of corn, other grains like barley or rye, yeast, and water.

Corn as the primary ingredient

Corn is the superstar ingredient in bourbon production, contributing to over half of what we refer to as the ‘mash bill’.

Humbled corn kernels are cracked open, releasing their sweet starches that form the foundation of this American spirit.

Notably, law mandates a minimum inclusion level of 51% corn – but some recipes boast up to 80%. It’s really down to the distiller’s preference and influences everything from taste profile to texture.

Moreover, corn dominance is non-negotiable for an authentic bourbon designation; any deviation means you’re essentially making another whiskey variety!

Hence, it’s clear why high-quality corn remains a cherished asset in every master distiller’s arsenal.

Other grains

In addition to corn, other grains like barley, rye, or wheat are often used in the production of bourbon. These grains play a crucial role in creating the unique flavor profile of this beloved American whiskey.

Barley is commonly used for its enzymes that aid in fermentation, while rye adds a spicy and robust character to the final product. Wheat, on the other hand, lends a soft and smooth quality to the bourbon.

By carefully selecting and combining these different grains in the mash bill, distillers can create a wide range of bourbon variations with distinct taste profiles.

So when you take a sip of your favorite bourbon, remember that it’s not just about corn – there’s an artful blend of other grains working behind the scenes as well.

Yeast

Yeast plays a vital role in the production of bourbon. It is responsible for fermenting the mash, converting sugars into alcohol and carbon dioxide. This process gives bourbon its distinct flavor and aroma.

While different strains of yeast can be used, each distiller often has their own proprietary strain that they believe contributes to the unique characteristics of their bourbon.

The choice of yeast can greatly influence the final taste profile of the spirit, showcasing flavors ranging from fruity to spicy notes.

Without yeast, bourbon wouldn’t exist as we know it today – a true American classic with a rich heritage and unmistakable allure.

Water

Water is a crucial ingredient in the production of bourbon. It is used throughout the manufacturing process, from mixing the mash to diluting the final product before bottling.

The purity and quality of water greatly impact the flavor and character of bourbon. Distilleries carefully source their water from natural springs or wells to ensure it meets specific standards.

Read More : What Is Courvoisier Updated 07/2025

The mineral content in the water contributes to unique flavors and helps yeast ferment properly during fermentation.

Ultimately, water plays a vital role in creating the smooth and distinct taste that makes bourbon so beloved by alcohol enthusiasts worldwide.

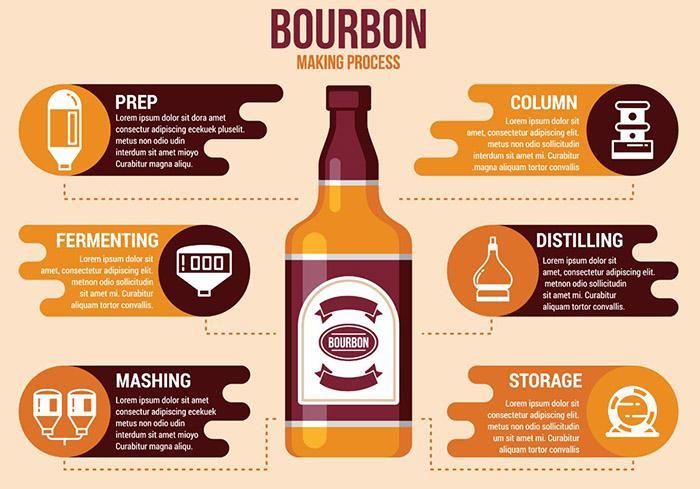

The Manufacturing Process of Bourbon

The manufacturing process of bourbon involves several key steps, including mash production, fermentation, distillation, and aging in new charred oak barrels.

To learn more about how bourbon is made and the legal requirements for its production, continue reading.

Mash production

To make bourbon, the first step is mash production. This involves combining the grains, yeast, and water to create a mixture called the mash. The main ingredient in bourbon is corn, making up at least 51% of the mash bill.

Other grains like barley, rye, or wheat can also be added to give it different flavor characteristics. The yeast helps ferment the sugars in the grains and converts them into alcohol.

It’s important to note that bourbon must be made from a fermented mash of grain – this sets it apart from other distilled spirits like vodka or rum which can be made from any raw material.

So essentially, mash production is where all these ingredients come together to lay the foundation for creating delicious bourbon.

Fermentation

Fermentation is a crucial step in the production of bourbon. After the mash is prepared with corn, grains like barley or rye, yeast, and water, it goes through a process called fermentation.

During this stage, yeast breaks down the sugars in the mixture and converts them into alcohol. This creates a liquid known as the “distiller’s beer” or “wash.” The wash typically contains around 6-12% alcohol by volume (ABV).

The duration of fermentation can vary but usually takes several days. Once it’s complete, the wash is ready for distillation to further concentrate and refine its flavors.

Distillation

The distillation process is a crucial step in the production of bourbon. After the mash has been fermented, it undergoes distillation to separate the alcohol from the solids.

Distillation involves heating the fermented mash, causing the alcohol to vaporize and rise through a still.

The vapor is then condensed back into liquid form, resulting in a high-proof distilled spirit. This process helps create bourbon’s distinct flavors and characteristics, as well as ensuring its smoothness.

By carefully controlling the distillation process, master distillers can achieve the desired balance of flavors that make bourbon such a beloved American whiskey.

Aging in new charred oak barrels

Bourbon gets its distinct flavor and rich amber color from aging in new charred oak barrels. The use of new barrels ensures that the bourbon extracts unique flavors from the wood, such as vanilla, caramel, and toasted oak.

As the bourbon matures over time, it absorbs these flavors while also mellowing out any harshness in the spirit.

Additionally, the charring of the barrels creates a layer of charcoal on the inside, which acts as a natural filter to remove impurities and further enhance the smoothness of the bourbon.

This careful process of aging in charred oak barrels is what gives bourbon its characteristic depth and complexity. So when you sip on a glass of this classic American whiskey, know that its journey to perfection can be traced back to those carefully crafted barrels.

The Legal Requirements for Bourbon Production

Minimum 51% corn content

Read More : What Is Spiced Rum Updated 07/2025

Bourbon, the classic American whiskey, is known for its rich and distinct flavor profile. One key element that sets bourbon apart from other spirits is its minimum 51% corn content in the mash bill.

This requirement ensures that corn plays a prominent role in creating the unique taste of bourbon. The high percentage of corn contributes to its smooth and slightly sweet flavor, giving it a signature character that fans of this beloved spirit appreciate.

So when enjoying a glass of bourbon, you can savor the distinctive influence of corn as an essential ingredient in every sip. Cheers!

Aging in new charred oak barrels

Aging in new charred oak barrels is a crucial step in the production of bourbon. These barrels play a significant role in shaping the flavor and character of the spirit. By law, bourbon must be aged in these specific barrels to be classified as such.

The charring process caramelizes sugars within the wood, which then infuse into the liquid during aging, creating rich and complex flavors.

Furthermore, these new barrels allow for greater interaction between the whiskey and wood, resulting in a smoother and more mellow taste profile.

The use of oak also imparts desirable aromas like vanilla and spice to enhance the overall drinking experience.

So next time you sip on a glass of bourbon, remember that its unique flavors are born from this careful aging process in new charred oak barrels.

Specific ABV (Alcohol by Volume) requirements

Bourbon, as a distinct type of whiskey, has specific requirements regarding its Alcohol by Volume (ABV) content.

By law, bourbon must be distilled to no more than 160 proof (80% ABV) and entered into the barrel for aging at no more than 125 proof (62.5% ABV).

Additionally, when it is bottled for sale, bourbon must have a minimum ABV of 40%.

These regulations ensure that bourbon maintains its unique flavor characteristics while also providing consumers with a consistent alcohol content in every bottle.

So whether you’re sipping it neat or mixing it into your favorite cocktail, you can trust that the ABV of your bourbon will provide an enjoyable experience.

Geographical considerations (not limited to Kentucky)

Bourbon is often associated with Kentucky, but it’s important to note that it can be made anywhere in the United States.

While Kentucky has a long history of bourbon production and is considered the heartland of this beloved American spirit, there are distilleries across the country that produce exceptional bourbons.

In fact, some states like Tennessee have their own unique style of corn-based whiskey known as Tennessee whiskey.

So if you’re a bourbon enthusiast, don’t limit yourself to just one region – explore the diverse flavors and styles that can be found throughout America.

Whether it’s from Kentucky or another state, each bottle of bourbon tells its own story and offers a taste of our rich American heritage.

Conclusion

In conclusion, bourbon is made from a mash that consists of at least 51% corn, along with other grains like rye or wheat.

It undergoes the process of fermentation and distillation before being aged in new charred oak barrels.

These ingredients and manufacturing techniques contribute to the distinct flavor profile that sets bourbon apart from other types of whiskey.

So next time you sip on a glass of this American classic, you can appreciate the craftsmanship behind its creation.

Sources: https://chesbrewco.com

Category: Wine