Ever wonder what’s in that frothy beverage you love to sip on a sunny afternoon?

Beer, one of the oldest and most beloved alcoholic drinks worldwide, is primarily made from water, grains, yeast, and hops.

You Are Watching: What Is Beer Made Of Updated 07/2025

This article unravels the key ingredients in beer and how they’re transformed through brewing into your favorite brewski.

So let’s dive headfirst – it’s time to unlock the secrets behind your pint glass!

The 4 Basic Ingredients of Beer

Water

Water holds the title of being the most crucial ingredient in beer production, accounting for up to 95% of its content.

It’s not just any water that makes the cut; the mineral composition of water used significantly influences a beer’s taste and quality.

This is why breweries often purify their water before use, adjusting minerals and pH levels to ensure consistency in their brews.

The role of water goes beyond simply providing a base for other ingredients; it also acts as a solvent during brewing, assisting in extracting flavors from grains and hops while promoting yeast health during fermentation.

Grains

Beer is primarily made from grains such as barley, wheat, oats, and rye. These grains provide the essential starches that are converted into sugars during the brewing process.

Barley is the most commonly used grain in beer production due to its high enzyme content, which helps break down complex carbohydrates into fermentable sugars.

Wheat adds a smooth and creamy texture to beers, while oats contribute to a velvety mouthfeel. Rye imparts a spicy and earthy flavor profile to certain beer styles.

Each of these grains brings its unique characteristics to the brewing process, resulting in a wide range of flavors and types of beer available for us to enjoy.

Yeast

Yeast is a crucial ingredient in the beer-making process. It’s responsible for fermentation, where it consumes sugars and converts them into alcohol and carbon dioxide.

This natural microorganism plays a significant role in giving beer its distinct taste and aroma.

Different types of yeast can produce a wide range of flavors, from fruity to spicy, adding complexity to the final product.

Without yeast, beer wouldn’t exist as we know it today. So next time you raise your glass, remember that these tiny organisms are working hard behind the scenes to bring you that delicious pint of brew.

Hops

Hops are an essential ingredient in beer that adds a unique flavor and aroma. These small green flowers contain natural acids, oils, and resins that balance the sweetness of the malted barley and provide a refreshing bitterness to the brew.

Hops also act as a natural preservative, helping to prevent spoilage and extend shelf life.

In addition to their taste and preservation properties, hops have been found to possess antimicrobial qualities that can contribute to overall beer quality.

With thousands of different hop varieties available today, brewers have endless options for creating distinct flavors in their beers.

So, next time you take a sip of your favorite beer, remember that hops play a crucial role in its complex taste profile!

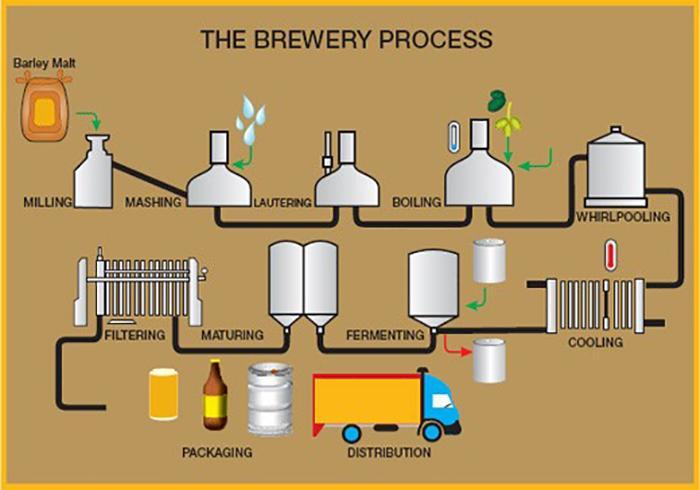

The Beer Brewing Process in 5 Steps

Sanitizing

Sanitizing is a crucial step in the beer brewing process as it helps ensure that the equipment and utensils used are clean and free from harmful bacteria or contaminants.

Brewers understand the importance of maintaining a sterile environment to prevent any unwanted flavors or spoilage during fermentation.

Read More : How To Open Beer Bottle Without Opener Updated 07/2025

By thoroughly cleaning and sanitizing their brewing equipment, including fermenters, hoses, and kegs, brewers can create a safe environment for yeast to do its job of converting sugars into alcohol.

This step is essential in producing high-quality beer that is not only enjoyable but also safe for consumption.

So next time you raise your glass, remember that behind every great-tasting beer lies a brewer who carefully takes care of cleanliness and hygiene throughout the entire brewing process.

Mashing

During the beer brewing process, mashing is a crucial step where the grains are mixed with hot water to extract their sugars.

This allows them to be converted by yeast into alcohol during fermentation.

The grains, such as malted barley and wheat, contain starches that need to be broken down into fermentable sugars.

By combining the grains with hot water in a process called mashing, enzymes naturally present in the grains activate and convert these starches into simple sugars.

This mixture, known as mash, is left for a specific period of time at a controlled temperature to allow enzymatic activity.

Once this step is complete, the resulting liquid (known as wort) contains sugars ready for fermentation by yeast.

Separation

During the brewing process, separation is a crucial step in beer production. After the wort (mixture of water and malted grains) has been boiled and hops have been added to create flavor and aroma, it needs to be separated from solid materials.

This separation ensures that only the liquid portion, which contains all the essential sugars and nutrients needed for fermentation, moves forward in the brewing process.

The solid materials are usually removed using various techniques such as filtration or centrifugation before transferring the liquid to fermentation vessels.

This vital step ensures that the beer is clear and free from any unwanted particles before it proceeds to fermentation where yeast works its magic by converting sugars into alcohol and carbon dioxide.

Wort Boiling

During the beer brewing process, one crucial step is wort boiling. After mashing and separating the liquid known as “wort,” it is time to bring it to a boil.

This boiling stage serves multiple purposes in the beer production process.

Firstly, it sterilizes the wort, killing any unwanted microorganisms that may hinder fermentation or spoil the final product.

Secondly, boiling helps extract bitter flavors from hops added during this stage, giving beer its distinct taste.

Lastly, wort boiling also aids in evaporating off undesirable compounds and concentrating flavors before moving on to fermentation where yeast works its magic by converting sugars into alcohol and carbon dioxide.

Fermentation

Fermentation is a crucial step in the beer brewing process. During fermentation, yeast converts the sugars present in the beer into alcohol and carbon dioxide.

This natural process takes place at room temperature and occurs after the wort (a mixture of water and malted grains) has been boiled and cooled.

As the yeast consumes the sugars, it produces alcohol, which gives beer its intoxicating properties, as well as carbon dioxide, responsible for creating those delightful bubbles we see in a glass of beer.

Without fermentation, there would be no alcohol or fizziness in our favorite brews!

Fun fact: Did you know that different types of yeast can produce varying flavors and aromas? That’s why brewers carefully select specific strains to achieve desired characteristics in their beers.

From fruity esters to spicy phenols, yeast plays a significant role in shaping each unique brew.

The Two Main Types of Beer

There are two main types of beer: ales and lagers. Want to know more about their distinct characteristics and brewing processes? Read on!

Ales

Ales are a type of beer that have been around for centuries and are known for their rich, complex flavors.

They are brewed using top-fermenting yeasts at warmer temperatures, typically between 60 to 75 degrees Fahrenheit.

The resulting beers tend to be full-bodied with a fruity or spicy aroma and taste. Ales can range from pale golden colors to deep amber hues, offering a wide variety of options to suit different preferences.

With more than 7,000 breweries producing these delicious brews in the United States alone, there is certainly no shortage of ale options to explore and enjoy!

Lagers

Lagers are a type of beer that is known for their crisp, clean taste. They are brewed using bottom-fermenting yeast strains at cooler temperatures, typically around 45 to 55 degrees Fahrenheit.

This slow fermentation process allows the flavors to develop more slowly and creates a smooth, mellow flavor profile. Lagers are often lighter in color than ales and have lower levels of hop bitterness.

Some popular examples of lagers include pilsners, bocks, and marzens.

With over 7,000 breweries in the United States alone, there is no shortage of delicious lager options to choose from for those who enjoy a refreshing beer without overpowering flavors or heavy textures.

Benefits of Drinking Beer

Drinking beer in moderation can have some surprising health benefits.

Firstly, beer is a rich source of vitamins and minerals. It contains a variety of B vitamins, such as riboflavin, niacin, and folate, which are essential for energy production and maintaining healthy cells.

Additionally, beer is packed with minerals like potassium and magnesium that play crucial roles in supporting heart health and maintaining proper muscle function.

Not only does beer provide important nutrients, but it may also help reduce the risk of certain health conditions. Research shows that moderate beer consumption has been linked to a lower risk of heart disease.

The alcohol content in beer can increase levels of high-density lipoprotein (HDL) cholesterol or “good” cholesterol while reducing low-density lipoprotein (LDL) cholesterol or “bad” cholesterol.

This balance helps to prevent clogged arteries and reduces the risk of cardiovascular problems.

Moreover, studies suggest that the hops found in beer offer antioxidant properties that can combat inflammation in the body.

Inflammation plays a role in various chronic diseases like arthritis and certain types of cancer.

Hops’ anti-inflammatory effects may contribute to their potential to provide protection against these conditions.

So while enjoying a cold brew with friends or at dinner might bring pleasure; always remember: it’s important to consume alcohol responsibly as part of an overall healthy lifestyle.

Conclusion

In conclusion, beer is made from four basic ingredients: water, grains or malts (such as barley and wheat), yeast, and hops.

These ingredients undergo a brewing process that includes steps like malting, mashing, boiling, fermenting, conditioning, and packaging.

With over 7,000 breweries in the United States alone, beer production has become a diverse art form with endless flavor possibilities.

So next time you enjoy a cold one, raise your glass to the careful craftsmanship of water, grains, yeast, and hops coming together to create this beloved beverage.

Cheers!

Sources: https://chesbrewco.com

Category: Beer